Products

-

Four-side hydraulic press series(Downward open type)

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing. High density braced sheetings as back worktop and pressure from the top and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

■ According to different working specifications(length or thickness), system pressure can be adjusted according to different pressure required. And there is pressure-recovery system , which ensure the constant pressure.

■Numerical control and hotkey operation, which reduce human factor and improve quality.

■ 4 workside,high efficiency.

■ Downward open type , which facilitate bigger and longer wood pieces’ loading and unloading.

-

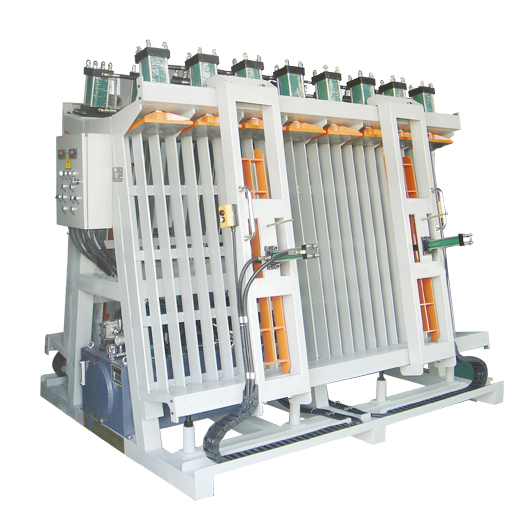

Four-side hydraulic press series (Sectional type)

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing. High density braced sheetings as back worktop and pressure from the top and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

■ According to different working specifications(length or thickness), system pressure can be adjusted according to different pressure required. And there is pressure-recovery system , which ensure the constant pressure.

■Numerical control and hotkey operation, which reduce human factor and improve quality.

■4 workside,high efficiency.

-

Two-side hydraulic press series (Normal type)

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing.

What services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW;

Accepted Payment Currency: USD, CNY;

Accepted Payment Type: T/T, Credit Card, L/C,

English, Chinese

■ According to different working specifications(length or thickness), system pressure can be adjusted according to different pressure required.And there is pressure-recovery system ,which ensure the constant pressure.

■ Numerical control and hotkey operation, which reduce human factor and improve quality.

There is a wide range of hydraulic press types. All are press machines that work with either fluid or hydraulic pressure. Based on Pascal’s principle, a hydraulic press works because pressure builds up throughout its closed system, exerting equal force within all areas of the container.

-

Single-side hydraulic press series (Normal type)

Single-side hydraulic press series (Normal type)Characteristics:

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing. High density braced sheetings as back worktop and pressure from the top and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

■ According to different working specifications(length or thickness),system pressure can be adjusted according to different pressure required. And there is pressure-recovery system ,which ensure the constant pressure.

How can I get a quotation?

Leave us a message with your purchase requests and we will reply you within one hour on working time. And you may contact us directly by Trade Manager or any other instant chat tools in your convenient.

Hydraulic presses have been around since the late 1700s. They are also called Bramah presses in tribute to inventor Joseph Bramah, a multi-talented man who developed the flush toilet. In fact, studying the motion of fluids when installing toilets helped him create the first hydraulic press.

-

Single-side hydraulic press series(Sectional type)

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing. High density braced sheetings as back worktop and pressure from the top and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

■ According to different working specifications(length or thickness), system pressure can be adjusted according to different pressure required. And there is pressure-recovery system ,which ensure the constant pressure.

■Sectional type, for shorter wood processing, more flexible and high efficiency.

-

Horizontal hydraulic press glulam press

Characteristic:

1.This machine adopts hydraulic principals characterized by a huge pressure and pressing.

Pressure-supplement system can set the upper and lower limit of pressure and resupply the pressure lost automatically.

2.Top pressure pusher can move in horizontal direction according to working pieces specification.

3.With upward-downward roller on worktop,which facilitate feeding.

4.All operation controlled by buttons and valves,easy to operate.

The horizontal hydraulic press glulam press is a type of machinery used in the manufacturing of glulam beams, which are laminated wood beams used in construction. This press applies hydraulic pressure to wood lamellas to form them into a strong, durable beam. The horizontal design of this press allows for easy loading and unloading of the wood for streamlined production.The press uses a combination of heat and pressure to bond the wood lamellas together using adhesive, resulting in a high-strength beam. After the wood has been pressed and bonded, it is cut to size and shaped based on the project specifications. Glulam beams are known for their strength, versatility, and sustainability, making them a popular choice in modern construction.Overall, the horizontal hydraulic press glulam press plays a vital role in the production of glulam beams, providing an efficient and effective method of manufacturing these important building materials.

-

Indefinite length auto finger jointer

The Indefinite length auto finger jointer is a type of woodworking equipment used to create strong and reliable finger joints in wooden pieces. The machine is designed to handle an indefinite length of wood and can automatically cut and shape the pieces with precision. This saves time and labor costs, allowing manufacturers to produce high-quality finger jointed wooden pieces at a faster rate. The machine can also handle a wide range of wood types and sizes, making it a versatile tool for woodworking manufacturing.

-

I beams press H beams press

Characteristic:

- This machine adopts hydraulic principals characterized by a stable motion speed,huge pressure and still pressing.

- Feeding by chain,the feeding speed is adjustable,which is very suitable for mechanization.

- Loading and unloading can carry out automatically.

- Tht pusher is adjustable in horizontal direction.

- With 2 worktop ,raise efficiency

- .I assume you are asking about the difference between I beams and H beams and how they are manufactured using a press. I-beams have two flat top and bottom surfaces with a tapered edge in the middle, while H-beams have a wider flange and a narrower web. Both beams are commonly used in construction and manufacturing for their strength and durability.To manufacture I beams or H beams, a hydraulic press is used to bend steel to the desired shape. The press applies pressure to the steel, causing it to deform and take on the shape of the die. The die is a piece of metal with a specific shape that is used to guide the steel as it is bent.The process of manufacturing I beams and H beams can vary depending on the manufacturer and the size of the beams being produced. However, the general process involves heating the steel to a specific temperature, passing it through the press to bend it to the desired shape, and then cooling it to set the shape. Once the beam is formed, it is often cut to the desired length and prepared for use in construction or manufacturing.

-

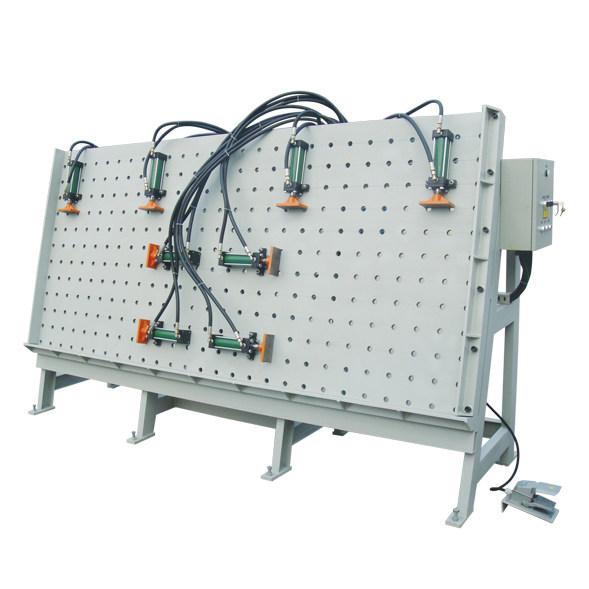

Double-side Door and Window Assembling Machine

Two Types of Frames

C-frame hydraulic presses can be used manually or automatically. As a rule they take up less floor space than other hydraulic presses because of their C-shaped frame. These presses, made of steel, are sturdy and have very little deflection.

The H-frame hydraulic press is used for a variety of operations. As a laminating press, it uses two places, one for heating, the other for cooling. Using the two together speeds up the process of laminating. When it is used as a transfer press, flat material is fed in, often rubber, metal blanks or plastic. It is passed from die to die by a feed bar finger. Most are made for heavy loads, as high as 3,500 tons, but there are smaller presses also.

A double-side door and window assembling machine is a piece of equipment used in the woodworking industry to assemble doors and windows. It has two worktables or stations, one for each side of the door or window frame. The machine applies glue to the joints, and the pre-cut pieces are assembled together on both sides simultaneously, saving time and improving efficiency. The machine also includes tools for drilling, grooving and cutting to ensure precision during the assembly process. Overall, the double-side door and window assembling machine is an essential tool for manufacturers who need to quickly and accurately produce doors and windows for construction projects.

-

MXB3525/MXB3530 Automatic finger shaper for beams

Characteristic:

1.The machine integrates trimming,milling teeth,waste crushing and deburring and other functions into one,trimming,deburring,crushing device and cutting blades are directly fixed to the motor,the cutting position can be adjusted to ensure the verticality of cross-section.

2.The dual high-speed shaft for milling teeth can be adjusted up or down according to actual requirement;the high-speed spindles applies accurate dynamic balance and sealed oil bearings to ensure machining accuracy.

3.Workbench of the manchine adopts imported rails,bearings to make it run smoothly.Rail,bearing has long service life.

4.The timber clamping device,using clamping and pneumatic sensor detection,making it safe and reliable.

5.The workbench is driven by hydraulic cylinder,travel speed can be individually adjusted,the forward speed is adjusted by one-way throttle valva mainly based on cutting amount;the backward includes rapid return and delecration to smooth stop.Additional material supporting device moving with the workbench,the machine has features of high efficiency and low labor intensity.

The MXB3525/MXB3530 Automatic Finger Shaper is a piece of machinery used to shape wooden beams. This machine uses an automated process to accurately shape the fingers in the wood to ensure a precise fit. It is ideal for use in factories or workshops where large quantities of beams need to be processed quickly and accurately. The machine is designed to be user-friendly and efficient, with advanced features such as automated feeding and precise cutting tools. With this machine, the process of shaping wooden beams is streamlined and the production time is significantly reduced.

-

Assembly presses glulam press

The Assembly Presses Glulam Press is a specialized piece of machinery used in the production of glued laminated timber (glulam). It is used to glue and press layers of timber together to create a larger and stronger structural component. The Glulam Press typically consists of a large hydraulic press that applies pressure to the timber layers while glue is spread between each layer. The process of gluing and pressing the timber layers together requires precision and expertise to ensure that the finished product meets industry standards. The Glulam Press is often used in the construction of bridges, buildings, and other large structures where high-strength and durability are essential.

-

Lamella press

Characteristics:

1. By pneumatic drive, it is featured by rapid and reliable action and uniform pressing, and can make gluing of face veneer flat and perfect by exerting pressure in the front or on the right of workpiece.

2. The machine, in the type of five-side rotation, has five working faces for continuous line production, ensuring higher working efficiency.

3. Length of workpiece can be freely adjusted by base plate to reach requirements stated in the order.

4.Worktable top made from polytetrafluoroethylene material is non-sticking to glue.

How Hydraulic Presses Work

The power in these presses is provided by hydraulic fluid, which produces the pressure that is generated. A press uses the standard parts for all types of hydraulic machinery, including pistons, hydraulic pipes, cylinders and a stationary die or anvil.

The pistons create a plunging or thrusting motion via liquid under pressure that exerts force. There are two primary cylinders, the small called the slave and the larger the master.

Oil or water is poured into the slave cylinder. As pressure builds is exerts force onto the piston in the larger cylinder. This larger piston then presses in the master cylinder. The action makes the punch connect with the die, which leads to deforming the metal into the shape that is desired.

-

Glulam press

Characteristics:

1.This machine adopts hydraulic principles characterized by a stable motion speed,huge pressure and still pressing.You can set a limit to the working pressure,when there is any loss of pressure,the pressure-supplement will start up.

2.Working length,width and thickness is customized according to different requirements.

3.Downward-open type,which facilitate loading an unloading.

To produce straight beams, a hydraulic press can be used to apply pressure and bend the wood into the desired shape. The press applies force evenly across the material, allowing for consistent shaping and minimizing the risk of cracking or splitting.To create a straight beam, the wood is placed between two flat, metal plates in the hydraulic press. The plates are then tightened, applying pressure to the wood and bending it into shape. The pressure is applied gradually, allowing the wood to slowly adjust to the new shape without being damaged.Once the desired shape is achieved, the press is released and the wood is allowed to cool and set in the new position. The resulting straight beam is strong and durable, making it ideal for use in construction projects.

-

Bladder moldings hot press

Characteristic:

1. Wide application: Suitable for butt joint of T-shaped or L-shaped material in furniture, door and window and decorative moulding instead of air nail gluing process.

2. High production efficiency: Every working face has the same presser foot which can be used for glue joint of T-shaped or L-shaped materials in different specifications only by simple setting.

3. Stable and reliable quality: Flat and smooth worktable and the open design of joint working area are convenient to find and correct mistakes to ensure correct butt joint.

4. Safe operation, environment protection and energy conservation: Freedom from electric drive is good for avoidance of electric damages, reduction of maintenance cost and electric power consumption, so the machine is intrinsically safe.

Production process—Laser cutting

High precision cuttingISO 9001 Quality control

Painting workshop, machine color can be customized -

Arched glulam press hydraulic glulam press

A hydraulic glulam press is a machine designed specifically to bend and shape glued laminated timber (glulam) into curved or arched forms. Glulam is a composite material made by bonding together several layers of solid wood using industrial adhesives. It is widely used in construction for its strength, durability, and aesthetic appeal.The hydraulic glulam press works by applying pressure to the glulam beams to bend them into the desired shape. The press consists of a bed, or platen, that supports the glulam beam and hydraulic cylinders that apply pressure to the beam. The platen can be shaped to match the curve or arch that is being produced.The glulam beam is first prepared by cutting it to the required length and width. It is then placed in the hydraulic press and clamped into position. The hydraulic cylinders are activated to bend and shape the beam into the desired form. After the bending process is complete, the glulam beam is allowed to cool and set in its new shape.Overall, a hydraulic glulam press is an important tool for the production of curved and arched glulam beams. Without this machine, it would be very difficult and time-consuming to produce these types of architectural features in a cost-effective manner.

-

MHZ1546/1552/1562 Automatic figer jointer series

The MHZ1546/1552/1562 Automatic finger jointer series is a type of woodworking equipment used to create finger joints in wooden pieces. The machine utilizes advanced technology to precisely cut and shape the wood, ensuring a strong and durable joint. This series is designed for high volume production and can handle a wide range of wood types and sizes. The automatic operation makes the process efficient and saves time and labor costs. Overall, the MHZ1546/1552/1562 series is a reliable and essential tool for woodworking manufacturers who need to produce high-quality finger jointed wooden pieces.

-

Hollow wooden forming hot machine

A hollow wooden forming machine is a piece of equipment used in the woodworking industry to create hollow wooden objects such as chairs, tables, or other furniture items. The machine uses a template or mold to shape the wooden pieces, which are then assembled using glue or other fasteners. The forming machine can be used to create a variety of shapes and sizes, and it is an essential tool for furniture manufacturers who need to produce high volumes of pieces quickly and efficiently. Overall, the hollow wooden forming machine is a valuable piece of equipment in the woodworking industry that helps to streamline production and increase output.

-

Bladder multifunction press lamella press

Characteristics:

1. By pneumatic drive, it is featured by rapid and reliable action and uniform pressing, and can make gluing of face veneer flat and perfect by exerting pressure in the front or on the right of workpiece.

2. The machine, in the type of five-side rotation, has five working faces for continuous line production, ensuring higher working efficiency.

3. Length of workpiece can be freely adjusted by base plate to reach requirements stated in the order.

4.Worktable top made from polytetrafluoroethylene material is non-sticking to glue.

The Bladder Multi-Function Press or Lamella Press is a specialized machine used in the woodworking industry to create curved plywood panels or laminates. The machine uses a hydraulic system to apply pressure to the layers of wood, which are bonded together to form a single sheet. The unique design of the Bladder Multi-Function Press allows for the formation of complex shapes and curves that are not possible with other types of presses. This press is commonly used in the production of curved furniture, musical instruments, and architectural elements such as curved walls or ceilings. The press can be programmed to create a wide range of shapes and sizes, making it a versatile tool for any manufacturer that requires quality curved plywood or laminates.

-

Four-side hydraulic press series(upward open type)

Performance characteristics:

1.Professional online service team, any mail or message will reply within 24 hours.

High density braced sheeting as back worktop and pressure form the above and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

2.inside thehydraulic system there is pressure -guaranteed and pressure-resupply structure which keep pressure and enhance the quality of products.

3.4 work side,each side with 6 work groups,high efficiency.

4.The front pressure pusher can be moved according to the different working requirements.

5.The machine adopts hydraulic braking system ,hydraulic lock and safety brace by which safety is secured

-

Two-side hydraulic press series(Sectional type)

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing. High density braced sheetings as back worktop and pressure from the top and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

■ According to different working specifications(length or thickness), system pressure can be adjusted according to different pressure required. And there is pressure-recovery system ,which ensure the constant pressure.

■ Numerical control and hotkey operation, which reduce human factor and improve quality

■ Sectional type, for shorter wood processing, more flexible and high efficiency.

-

Flooring press for laminating

Types of Hydraulic Applications

Hydraulic presses come in a wide range of types, suited to specific purposes. Here is an overview of several applications:

Platen presses

The C-frame press is an example of a platen press. All use a ram as well as a solid, and have a surface that is designed with stability in mind. They can be used for banking, drawing, straightening, punching, bending, forming and timing.

Vacuum and laminating presses

Credit cards are made with these presses, which encapsulate several layers of plastic. These presses can also apply film.Stamping presses

These presses are commonly used in the auto and metal working field. They can cut and shape material with a process called deformation with die.

Transfer presses

Used most often in aerospace and the medical industry, these presses mold and stamp rubber.Forging presses

These presses are used strictly on metal. -

Automatic finger shaper MXB3512 MXB3516

Characteristic:

MXB3515 Automatic finger shaper

Quality assurance.

We have our own brand and attach much significance to quality. The manufacture of running board maintains IATF 16946:2016 Quality Management Standard and monitored by NQA Certification Ltd. in England.

Worktablels move speed is adjustable.

PLC electrical control.

Quality assurance.

The MXB3512 and MXB3516 are two variations of the Automatic Finger Shaper machine used in woodworking to shape and profile wood edges, especially for finger joints. These machines are designed for high-speed cutting, efficiency, and accuracy. They are equipped with a modern feed system that adapts to the thickness of the wood being processed. The MXB3512 and MXB3516 Automatic Finger Shaper machines are easy to use, with a straightforward operation. The wood is fed into the machine, clamped and positioned automatically. The machine then shapes the wood using specialized cutters, producing high-quality finger joints. The finished product is then ejected from the machine, ready for further processing or assembly.Overall, these machines are valuable tools in the woodworking industry because they increase production output while maintaining consistent accuracy. They are versatile and efficient, making them a must-have for many woodworking operations.

-

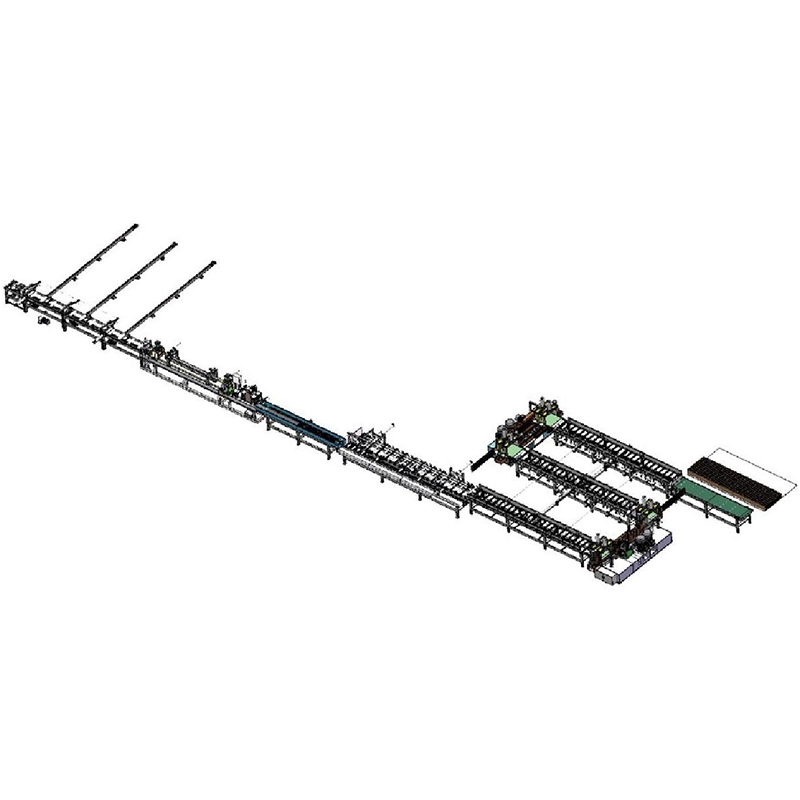

Heavy automatic finger jointer line

A heavy automatic finger jointer line is a type of woodworking equipment used to create a continuous length of lumber from shorter pieces. It uses a combination of hydraulic, electrical and pneumatic systems to quickly and accurately join multiple boards together end-to-end to create a longer piece of lumber. This type of line is commonly used in the manufacturing of furniture, construction materials, and other wood-based products. The jointer also includes high-tech controls to ensure precision cuts and reduce waste.

automatic finger joint line

It insist with two shaper machines and one pressing machine, connect with different conveyors thus no save labor, this line total power 48.4kw, space 24m, need about 2 operators, can make 6-7 pcs 6m wood per minute.We will be dedicated to upgrade of product and technical innovation in the operation philosophy of “First-rate Quality, Sophisticated Technology, High-quality Service”, and strive to bring customer greatest benefit.

Mr. Sun Yuanguang, President and General Manager, together with all staff, expresses our sincere thanks to customers at home and abroad who always give us support and encouragement, and we will march forward and improve quality and technical content of product for making customer satisfied. -

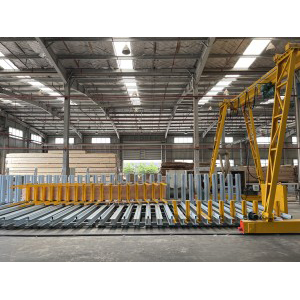

Preformed wall production line

A woodworking wall production line is a system of equipment and machinery used for the mass production of wooden walls or wall panels. The production line typically includes machines that cut, shape, and join the individual wooden pieces to form the completed wall or panel. Such lines can be used for manufacturing various types of walls, including prefabricated walls or modular walls used in home construction. The use of such production lines allows for greater efficiency and productivity in the woodworking industry.

Phone: +86 18615357957

Phone: +86 18615357957 E-mail: info@hhmg.cn

E-mail: info@hhmg.cn