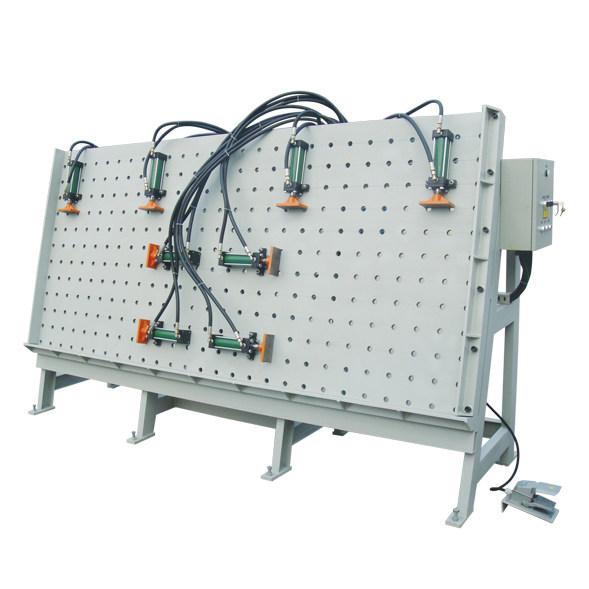

Assembly presses glulam press

Parameter:

| Model | MH2325/1 | MH2325/2 |

| Max working length | 2500mm | 2500mm |

| Max working width | 1000mm | 1000mm |

| Max working thickness | 80mm | 80mm |

| Top cylinder dia and quantity | Φ50*120*4 | Φ63*200*4 |

| Side cylinder dia and quantity | Φ50*120*4 | Φ63*200*2 |

| Rated pressure of hydraulic system | 16Mpa | 16Mpa |

| Rated pressure of air system | 0.6Mpa | |

| Overall dimensions(L*W*H) | 3200*950*1800mm | 3600*2200*1900mm |

| Weight | 1300kg | 2200kg |

The experimental study presented in this paper proposes a type of glulam beam with a hollow cross-section that can further optimise solid glulam beams. The study investigated the structural behaviour of glulam built-up box-section beams under four-point flexural bending at both ambient and elevated temperatures. A total of eleven 3100-mm long simply supported beam assemblies were experimentally examined: seven beams were tested at ambient temperature; and four beams were subjected to CAN/ULC-S101 standard fire. Five of the seven beam assemblies tested at ambient temperature were fabricated using self-tapping screws, while the other two assemblies were built using industrial polyurethane adhesive. Each built-up beam assembly was made of four glulam panels, all of 44 mm thickness except the bottom flange panel which had 86 mm thickness. Through ambient testing, it was concluded that when the spacing of the screws connecting the top and bottom flange panels of the built-up section to its web panels was decreased from 800 to 200 mm, the flexural resistanc

Phone: +86 18615357957

Phone: +86 18615357957 E-mail: info@hhmg.cn

E-mail: info@hhmg.cn